Where Your Concepts Become Reality…

Home »Founded in 1969, Cortina boasts a long tradition of providing quality parts at competitive prices. Our facilities and our people are what make the difference. From the initial part drawing through tooling and production, we utilize our talents to create cost-effective solutions for you.

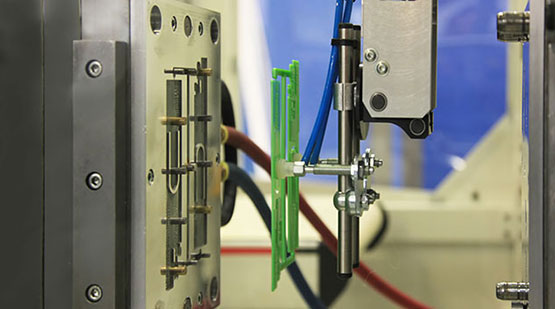

Our modern state-of-the-art ISO 9001:2015 certified facilities operate molding presses from 70 to 1100 tons, with shot capacity ranging from 3 to 180 ounces. Through the use of robotic part handling equipment, bulk storage silos, and overhead crane systems, we can deliver a consistent part, which exceeds your expectations for cost and quality. Our commitment continues beyond molding. We offer a total project management program which includes: Tooling, Hot Stamping, Painting, Assembly, and managed inventory and distribution. Combining our molding experience with our secondary operations and finishing capabilities, we offer shorter lead times and superior quality control.

Featured Services

Consumer & Industrial

At every stage in the process; design, tooling, production, in-mold decorating, finishing, packaging, and shipping, we’re adding elements of efficiency and reliability.

In-Mold Labeling

From concept to production utilizing the latest in injection molding equipment with state-of-the-art robotics, we can offer a complete program ensuring that the tooling through automation is properly integrated, on-line, and on budget every time!

Vehicular Lens Grade Molding

From Polycarbonate to Acrylic, our state-of-the-art molding facilities are equipped with the latest technology to manufacture your molded lenses and housings. Our in-house photometric testing laboratory makes Cortina the ideal candidate for all your reflex requirements.

Structural Foam

High-pressure foam molding eliminates sink marks and gives you a 90% better surface finish and in most cases, the surface is ready to paint or finish with little or no sanding.

Contract Manufacturing

Beyond a plastic component we can provide complete turn key production including assembly, pack-out and distribution.